We had a request late last week from one of our riders who recently purchased our RX3 lowering kit. Gerry walked me through the installation on Saturday and as I was preparing to write about it last night, I noticed that our good buddy Rob (who rode with us on the Western America Adventure Tour) had already posted a tutorial on the same topic over on the ChinaRiders.net forum. Rob did a great job (I’m a little jealous)! I thought it might make sense to post our tutorial on the same topic anyway, as seeing how this is done from a couple of folks’ perspectives might make it easier for all of you who want to install the lowering kit.

We had a request late last week from one of our riders who recently purchased our RX3 lowering kit. Gerry walked me through the installation on Saturday and as I was preparing to write about it last night, I noticed that our good buddy Rob (who rode with us on the Western America Adventure Tour) had already posted a tutorial on the same topic over on the ChinaRiders.net forum. Rob did a great job (I’m a little jealous)! I thought it might make sense to post our tutorial on the same topic anyway, as seeing how this is done from a couple of folks’ perspectives might make it easier for all of you who want to install the lowering kit.

So, the first step in this process is to get the rear wheel off the ground. We do the installation on a lift, as the bike is easier to work on when it is up on the air. You don’t need a lift to do the job, but you do need to get the rear wheel off the ground.

This is the longer suspension link, which will lower the bike once it has been installed. It’s what you get when you buy the lowering link from us.

We use a jack to lift the rear wheel. You don’t have to get it way up in the air; you just need a little clearance between the bottom of the rear wheel and the ground.

What we’re going to do is remove the stock suspension link (denoted by the center arrow). We are going to remove the pivot bolts at either end (denoted by the red arrows on the left and the right).

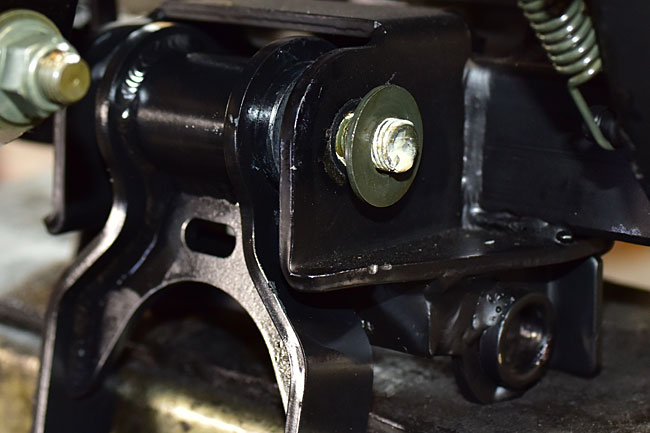

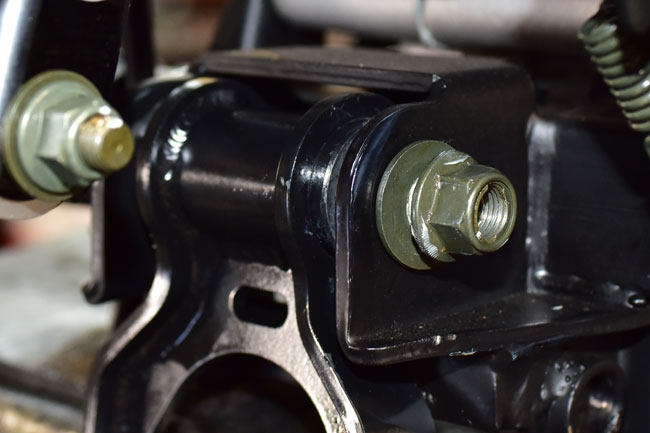

The self-locking nuts on the right side of the suspension link are 17mm; the bolt heads on the left side of the motorcycle are 15mm.

Remove the 17mm self-locking nuts and their washers from the right side of the suspension link on both the forward and aft pivot bolts, and remove the pivot bolts.

At this point, you can remove the stock suspension link.

After you have removed the suspension link, we advise reversing the hose clip on the rear brake’s rear hose attach point on the swingarm (there are two hose clamps and two attach points; we are describing the rear one). Remove the Allen bolt securing the clamp, rotate the clip 180 degrees (you don’t have to take it off the hose), and then reattach it so that the rear brake’s hydraulic line runs along the inside of the swingarm as you see in the photo below. We do this to assure clearance between the hose and the rear brake caliper when the rear suspension is fully compressed. We’ve checked this interface with the hose clamp in the original position and it clears the caliper; routing the hose as we show here adds additional clearance just to make sure these two items never come into contact with each other.

Let’s now remove the bearings and the seals from the original suspension link. The first part of this is to slide the bearing inner races out of both sides of the link.

Next, we’re going to gently pry the grease seals out of the link on both sides. The red arrow points to the grease seals. Do this carefully; we’re going to reuse the grease seals.

The grease seals have an inside and an outside. The side where you can see the spring faces into to the rear suspension link.

When you have removed the grease seals, you’ll be able to see the bearings inside the link. Note that when in place, there is about 6mm to 7mm of the link’s inner diameter exposed. That’s the area you see the red arrow pointing to below.

Now we have to remove the bearings from the link. The bearings are a press fit in the link, and the way to get them out is to heat the link. You don’t need to heat up it much; heating the rear link to about 250 degrees in this region is adequate. That won’t burn the paint and it will expand the link enough to allow us to drive out the bearings. Gerry uses a propane torch for this; you can also use a heat gun.

Once the link is warmed, use a couple of sockets and a hammer to drive out the bearings, as shown below.

You can also use a press to drive the bearings out, but most folks won’t have a press in their garage. We show you how to do it with a hammer and a couple of sockets for that reason.

Once the bearings are out, we recommend cleaning them thoroughly and then repacking them with bearing grease. We clean these parts in our solvent sink.

After the bearings and their inner races are clean, allow them to dry. Then apply bearing grease liberally, packing the bearings well and thoroughly coating the races. Gerry pushes the races into the bearings and rotates them several times to assure the bearing grease is appropriately distributed to all of the bearings’ inner surfaces.

Remove the inner races from the bearings, as we are now going to install the freshly packed bearings into the new rear suspension link. The process is the reverse of what we did before. Heat the rear link to allow it to expand. This will allow us to drive in the bearings.

We start the bearing with a brass hammer, and then drive them into the link the rest of the way with a vise and a bearing sleeve.

You want to drive the bearings into the link so that they go inside the link with about 6mm to 7mm of exposed inner diameter. After you’ve done that, reinstall the grease seals.

The grease seal surface should not protrude beyond the end of the link. The installation should look like the one below.

After the seals are in place, apply bearing grease liberally to the inside of the bearing.

Install the bearing inner races on both sides of the link, as you see below.

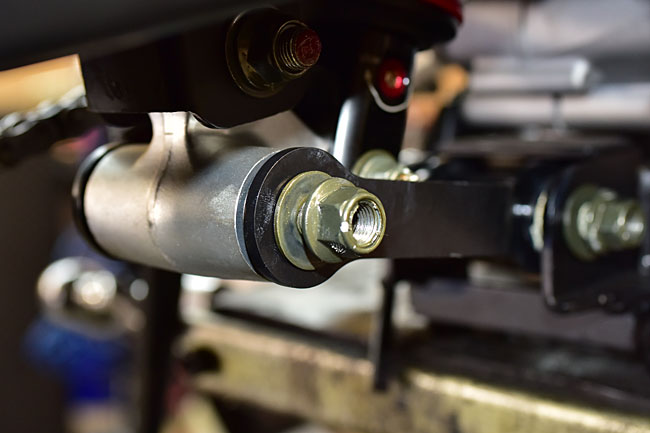

We can now install the new suspension link. Start with the front pivot point first. Push the pivot bolt through with the bolt head on the left side of the motorcycle. Push the bolt through the frame pivot points and the link, and then install the washer and the nut on the right side.

Lift the rear wheel to align the suspension link with its rear mounting holes, and repeat the bolt, washer, and nut installation process.

Tighten the rear suspension link bolts, and get out for a ride!

Most of the people who do this installation don’t do anything to the front suspension, but if you want to, you can lower the front of the bike, too. To do this, you can loosen the front forks in their upper and lower and triple tees, and move the forks up a bit. You can’t go too far in the front or you’ll hit the handlebars. If you want to lower the front end, please see our tutorial on fork maintenance for how to move the forks in the upper and lower triple tees.

And folks, that’s about it. If you don’t want to remove and reinstall the rear suspension link bearings, we can sell you a link that already has the bearings installed (just make sure you tell us that’s what you want when you order the lowering link).

SG250 San Gabriel Cafe Racer

SG250 San Gabriel Cafe Racer TT250 Enduro

TT250 Enduro