The TT250 electrical system is simple, easy to understand, and easy to maintain. This maintenance tutorial explains the system’s main components, their locations, their functions, and some suggestions in the unlikely event you’ll ever need to troubleshoot the system.

The TT250 has an 18-pole, 300-watt stator that puts out plenty of power. Many riders like to run accessories (heated vests, spotlights, heated grips, etc.), and on bikes with smaller electrical outputs, you can run the battery down while riding with all the accessories powered up. The TT250 won’t have this problem. It’s got the juice you need.

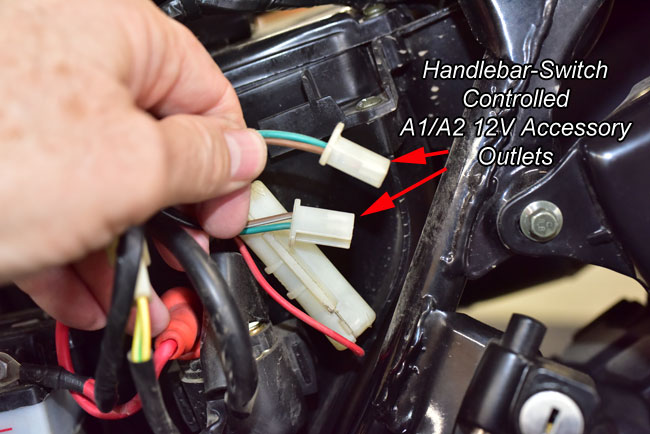

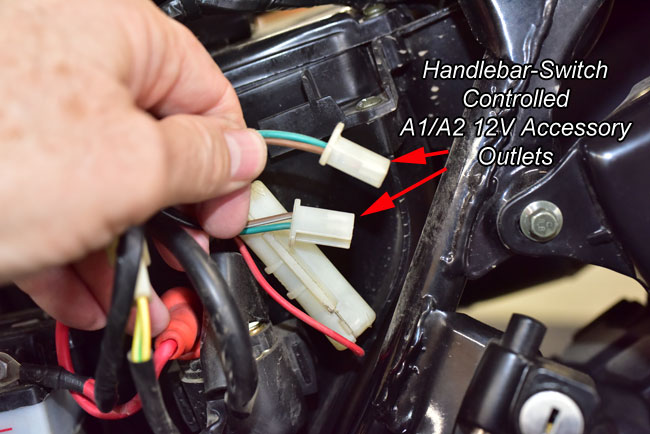

A cool feature on the TT250 is the built-in accessory outlets already wired into the main harness, and the accessories switch located on the right handlebar. On the non-US bikes, that switch was used for the headlights and parking lights. In the US, the headlights have to be on all the time, so the switch isn’t necessary. We didn’t want to give up the switch, though, so we’re using it to control the underseat accessories outlets.

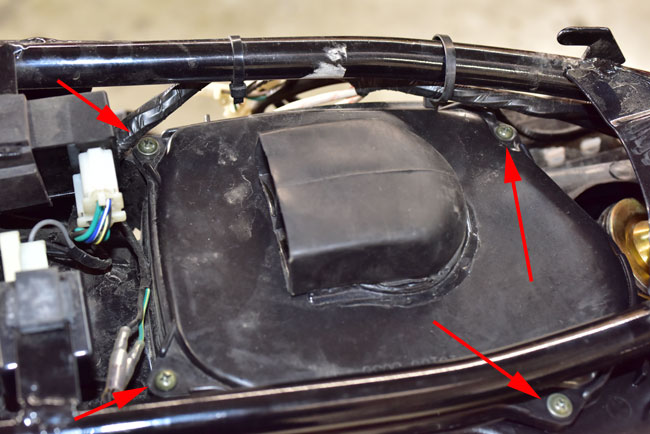

Let’s get on to the main attraction, and that’s the CSC TT250 electrical system and its components. Most of the electrical and electronic components on this bike are located under the seat and tank, and behind the headlight.

You can decide best which components you’ll need to remove based on which components you want to access. In this tutorial, we’ve removed the seat, the fuel tank, and the headlight so you can see everything. The first part of our tutorial below focuses on removing these items; the second part identifies various electronic component locations.

Body Panel, Seat, Fuel Tank, and Headlight Removal

Remove the rear body panels on the left and right side of the motorcycle. There’s a single bolt in each one. They pop off after you have removed the bolt.

Next, remove the seat. There’s a 10mm bolt on either side. Remove these bolts and pull the seat to the rear to remove it.

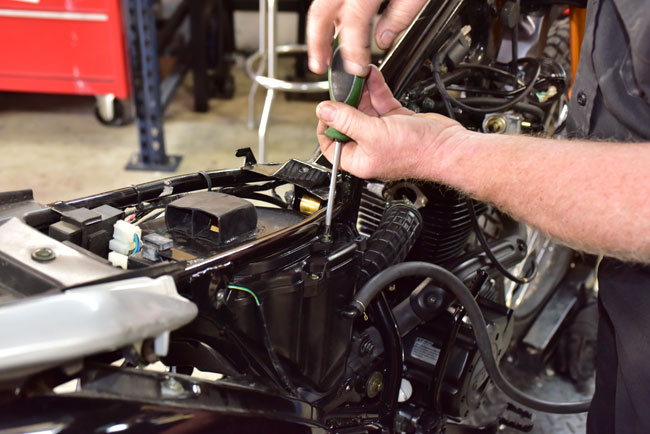

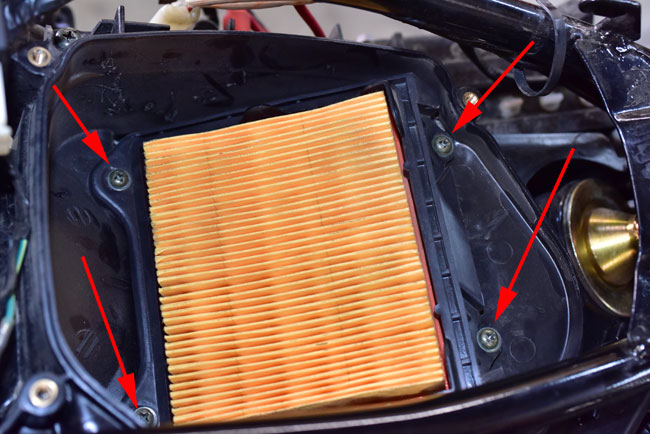

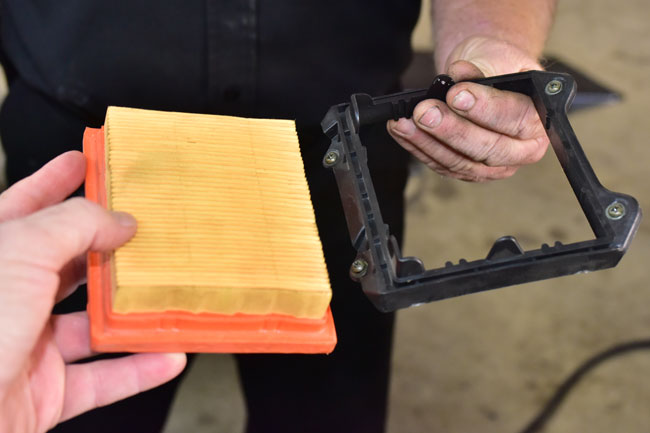

Removing the tank involves:

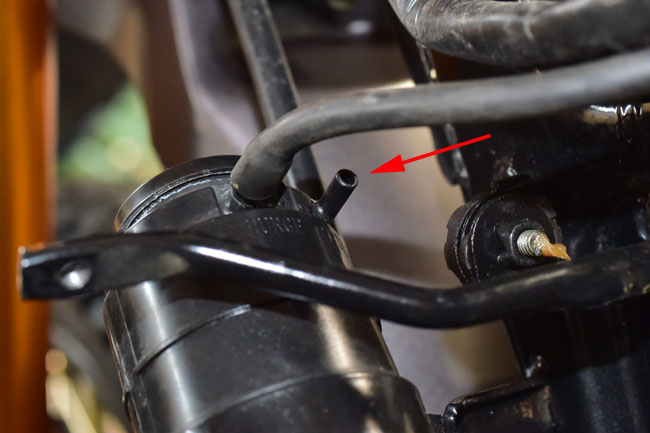

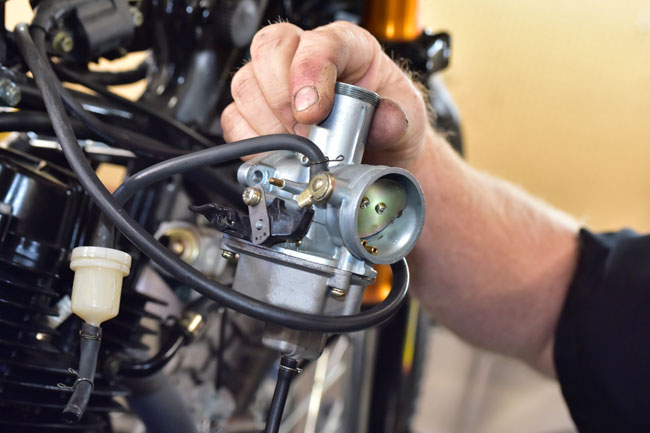

- Closing the fuel petcock.

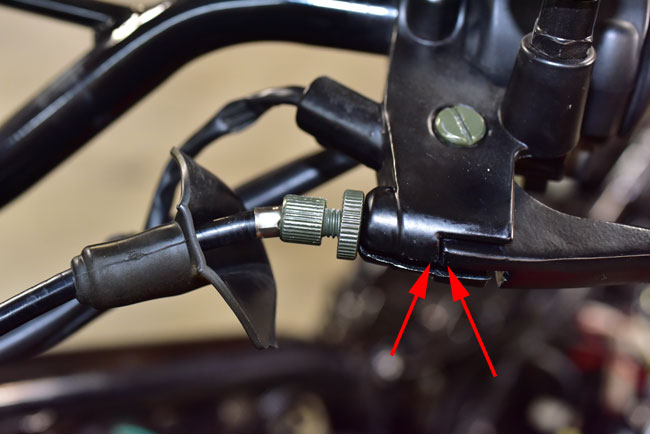

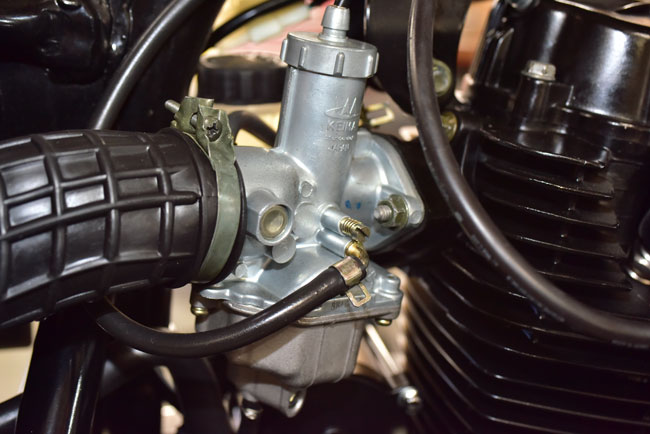

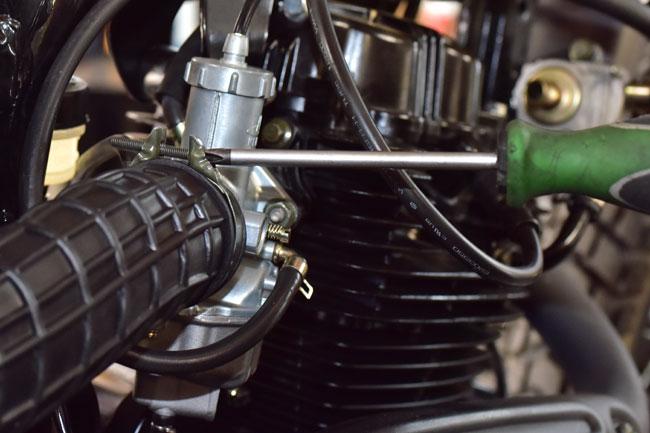

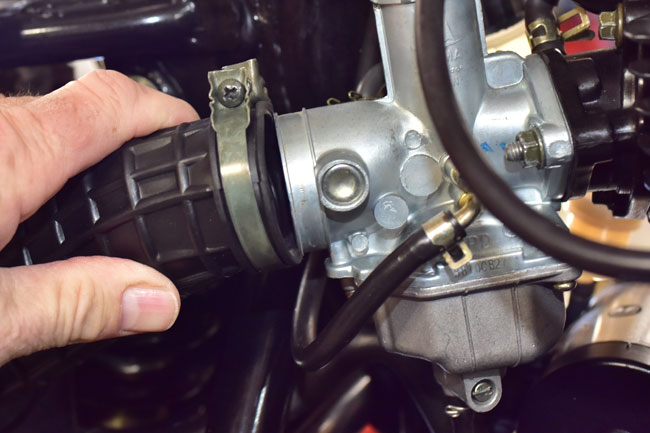

- Disconnecting the fuel line from the fuel petcock to the carburetor.

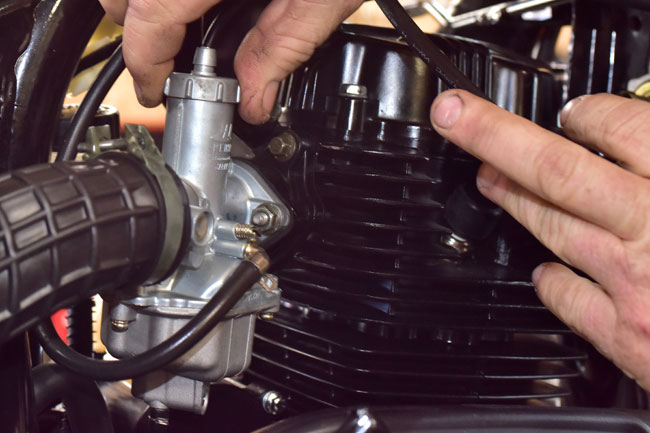

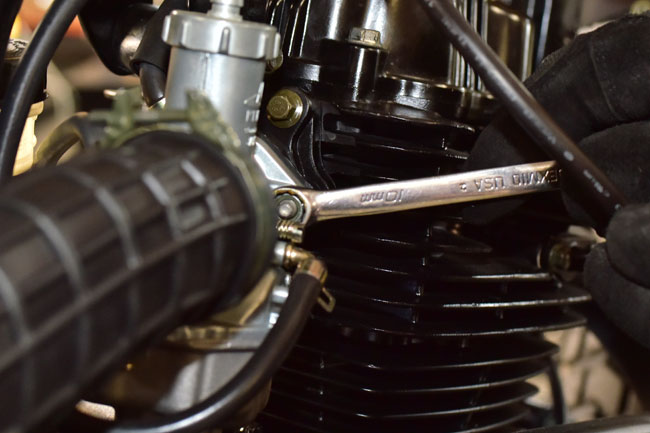

- Removing the 10mm bolt at the rear of the tank and the two Phillips head screws under the forward body panels (one on each side of the tank).

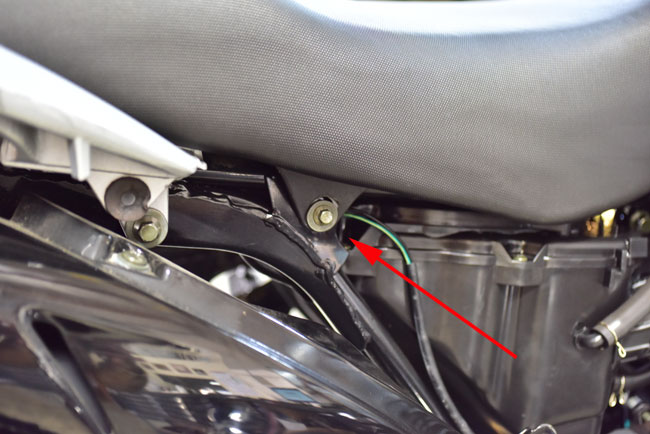

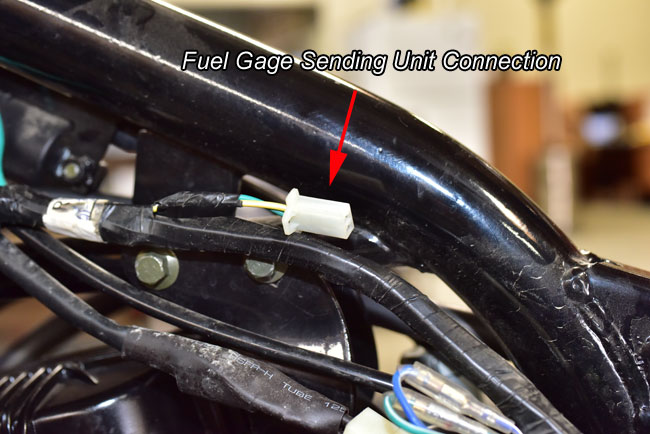

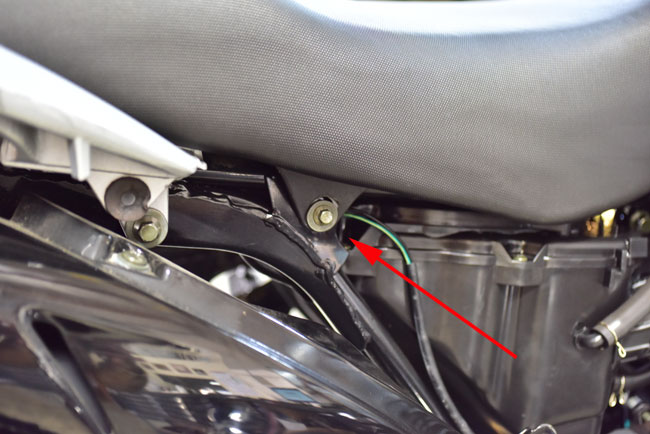

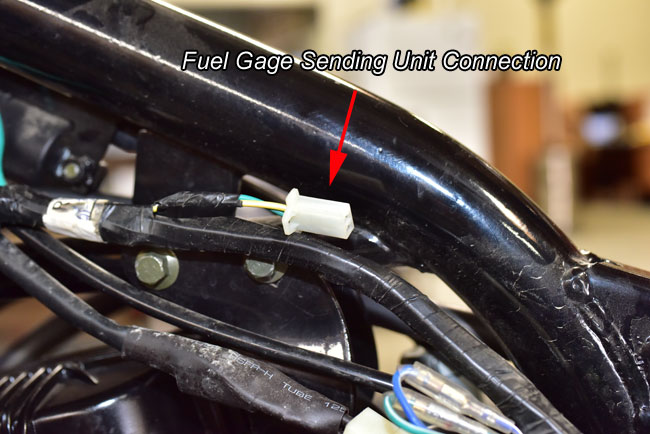

- Disconnecting the fuel sending unit connector plug.

- Disconnecting the tank vent line from the carbon canister.

These actions are shown in the photos below.

The headlight is removed by unscrewing two Phillips head screws on either side.

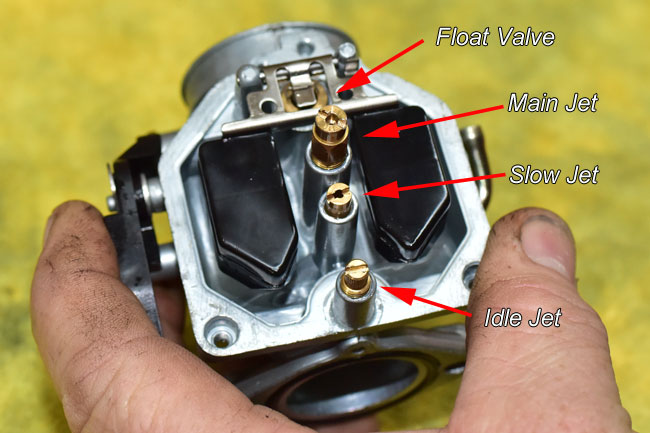

Electrical/Electronic Componentry

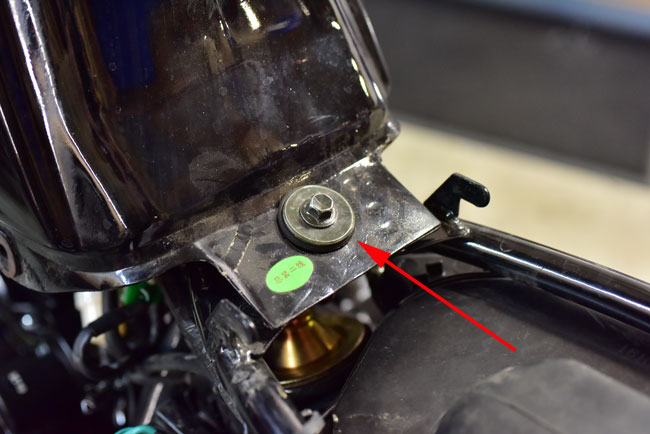

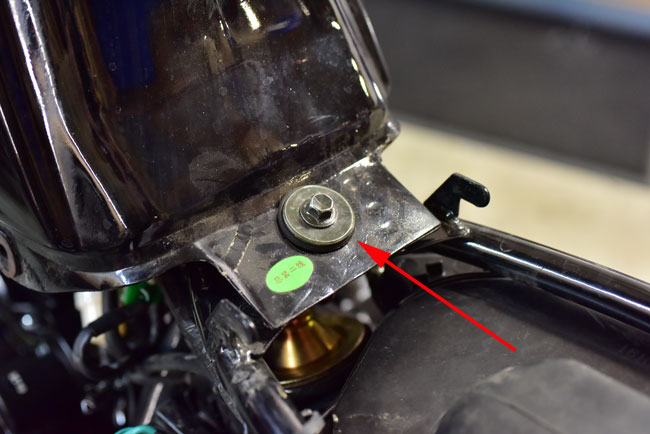

The first component is the ignition switch, located on top of the forks.

The headlight nacelle includes the harness running into the headlight bulb. In this photo, you can also see the wiring for the parking light (not separately operable on the North American bikes).

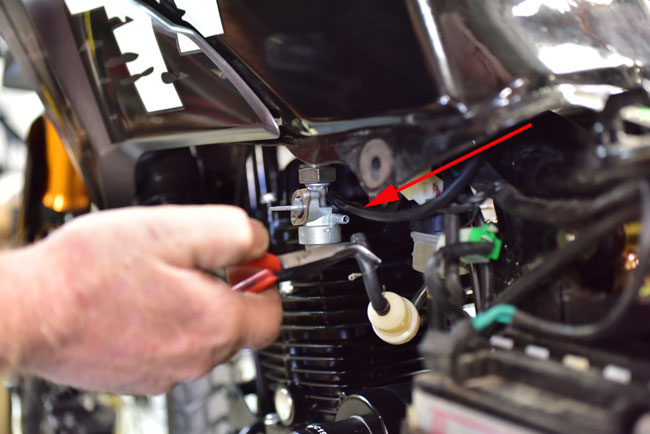

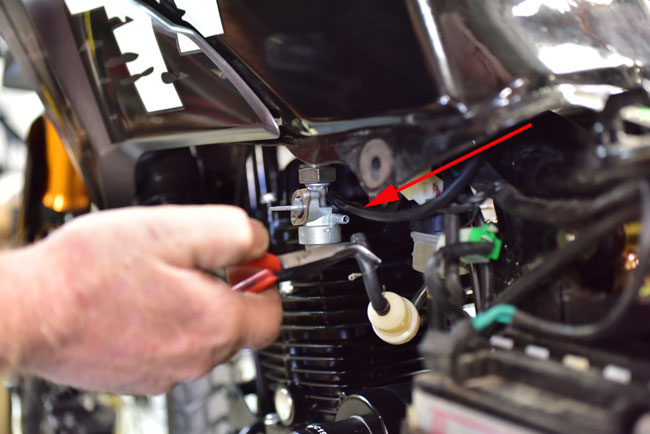

The horn is located on the right side of the frame near the front of the motorcycle. It is accessible without removing the fuel tank.

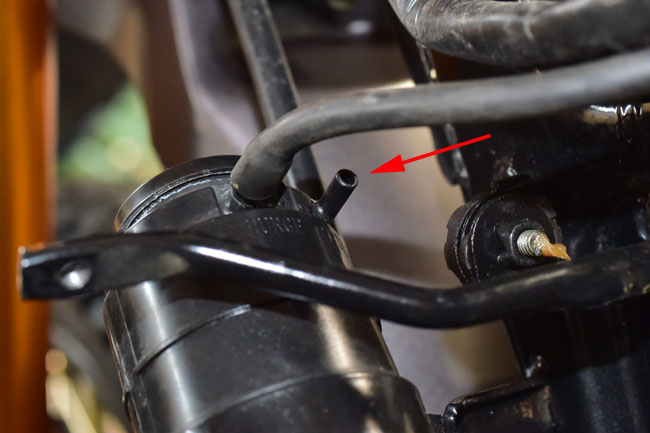

The connector from the fuel tank’s fuel gage sending unit to the fuel gage is underneath the tank. This is the half of the connector that stays with the motorcycle when the fuel tank is removed.

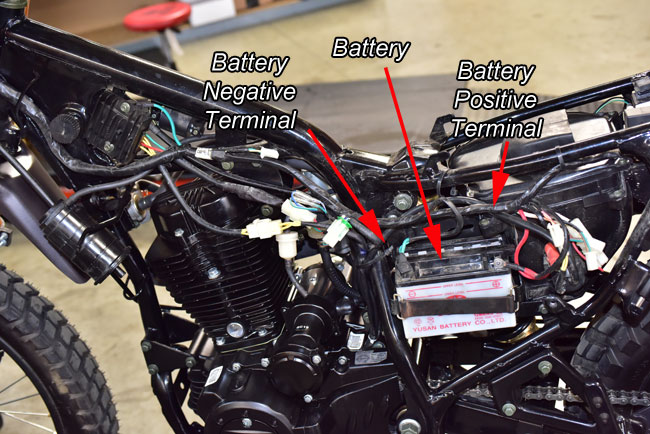

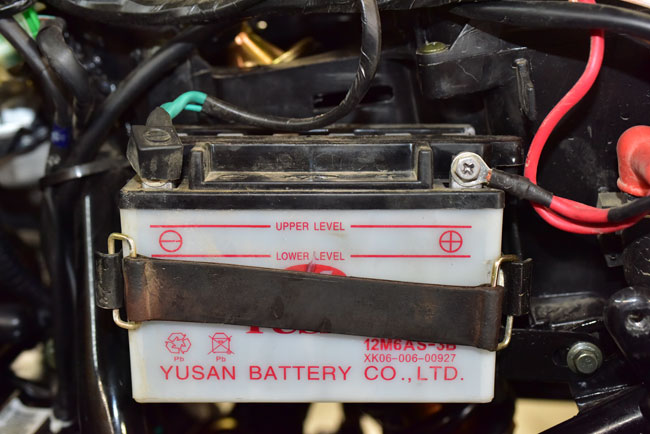

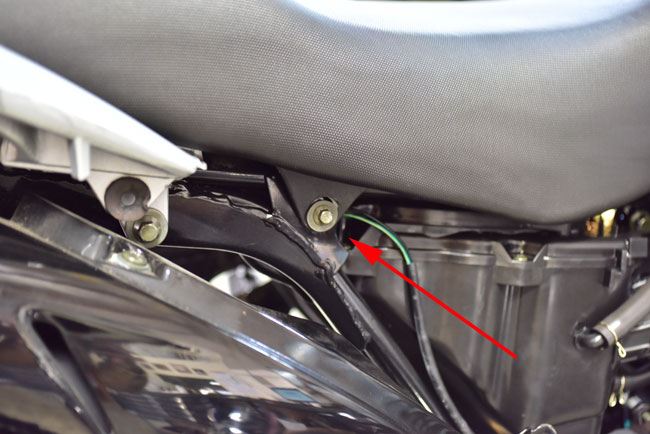

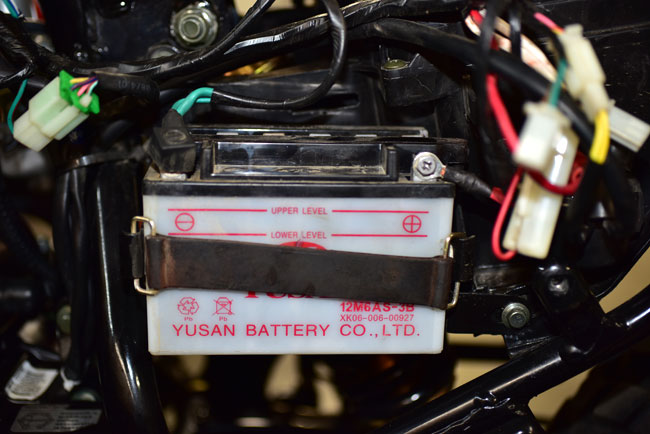

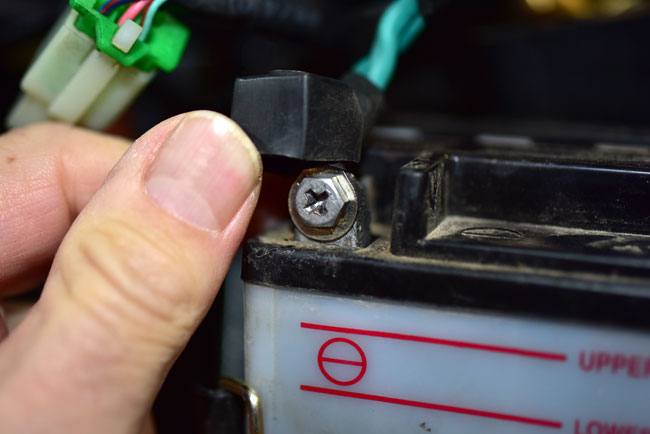

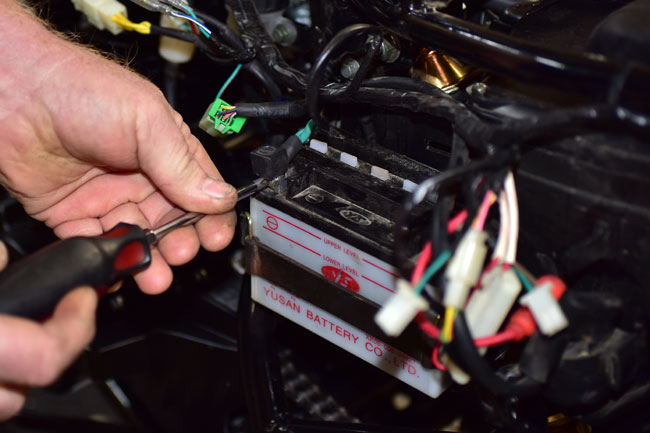

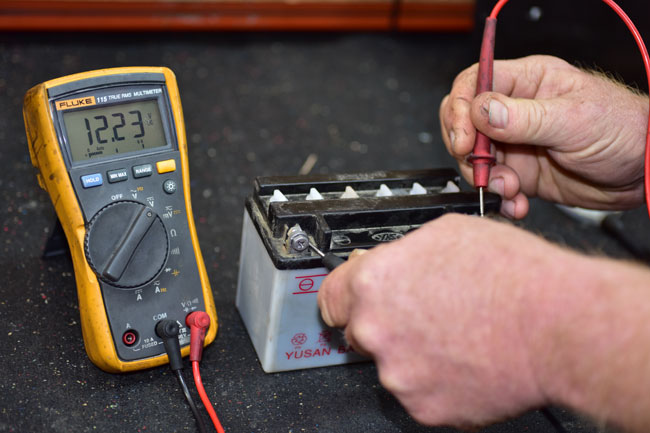

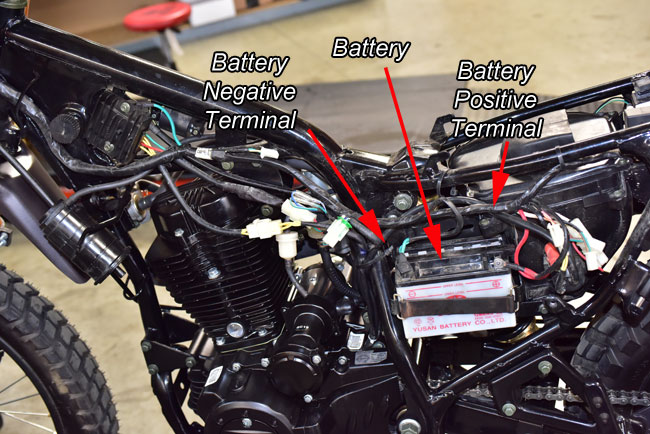

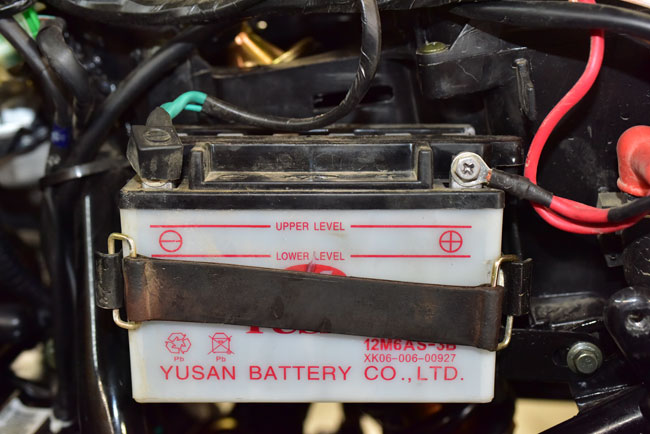

The battery is located on the left side of the motorcycle. It is accessible by removing the left rear body panel and the seat. It is secured by a rubber strap.

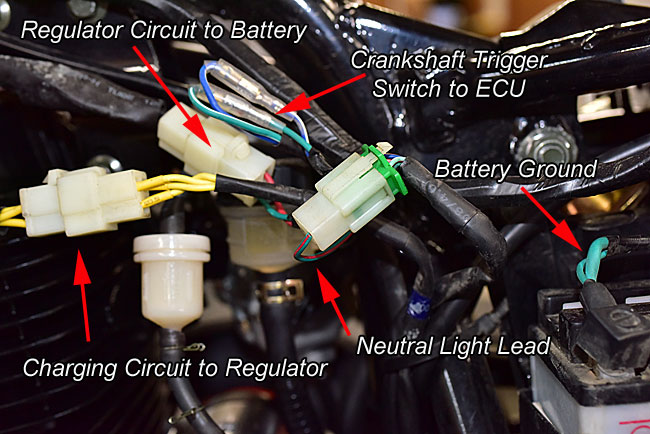

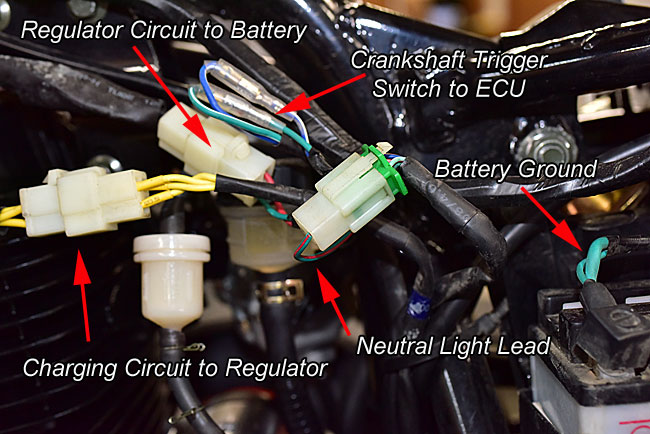

As you can see from the photo above, red is positive, and green is ground. Throughout the motorcycle, wires with green insulation are ground wires.

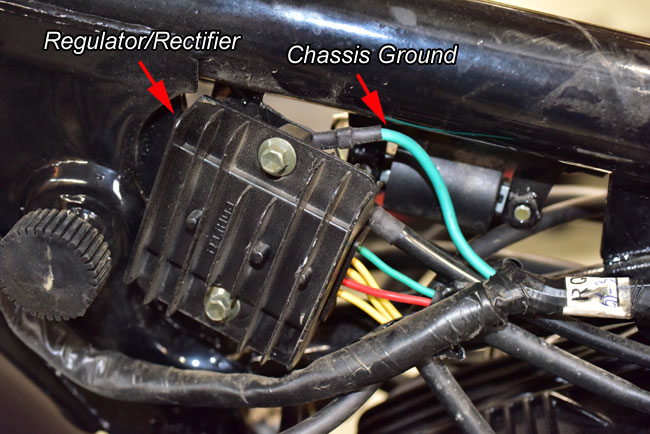

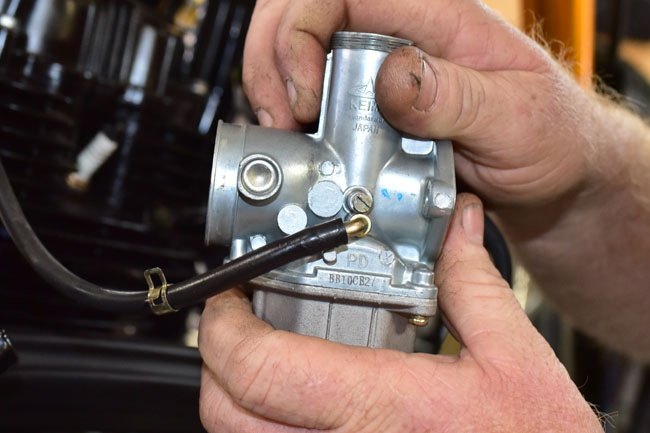

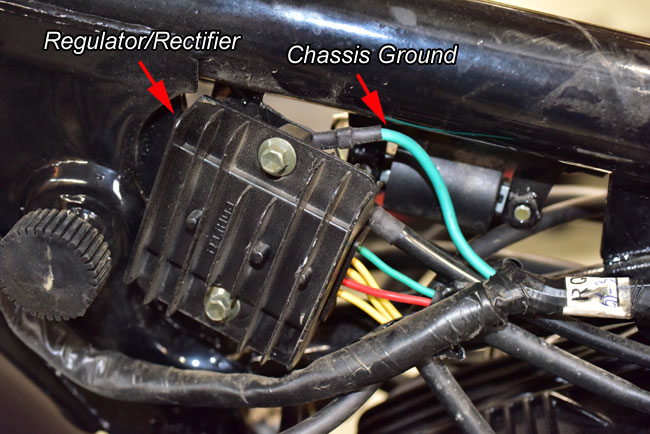

The regulator/rectifier is on the left side of the motorcycle near the front of the bike. It mounts to the frame beneath the fuel tank. If this component is not working, the battery will not charge properly or it may overcharge and boil over. The red and green wires go to the battery to charge it. The yellow wires come from the motorcycle’s stator.

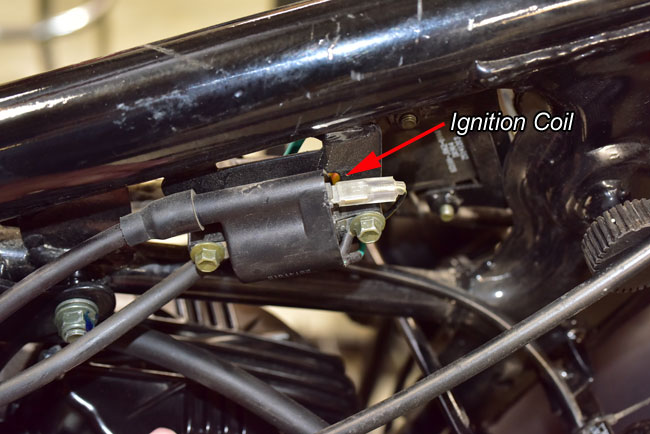

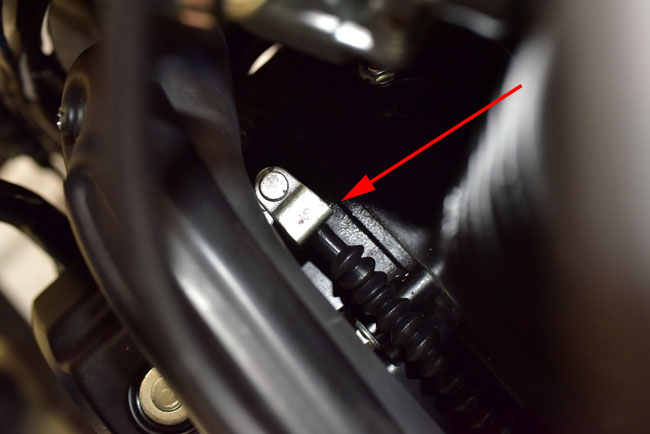

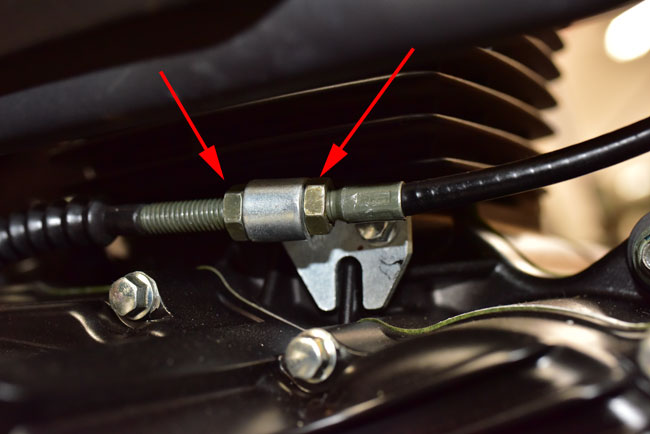

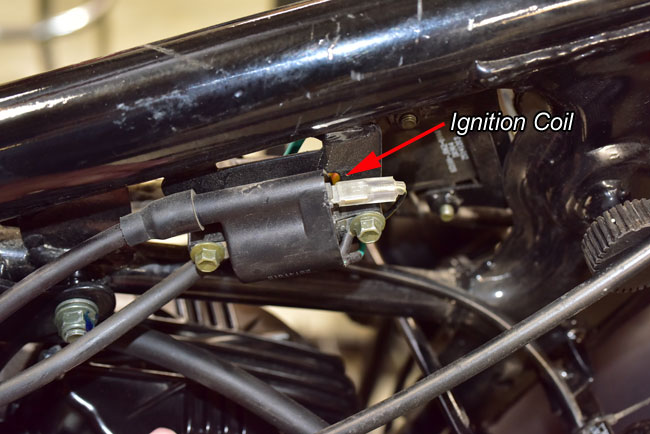

The ignition coil is located underneath the fuel tank on the right frame.

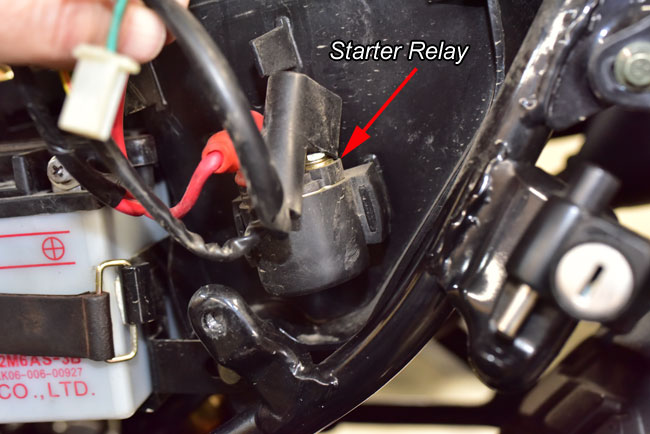

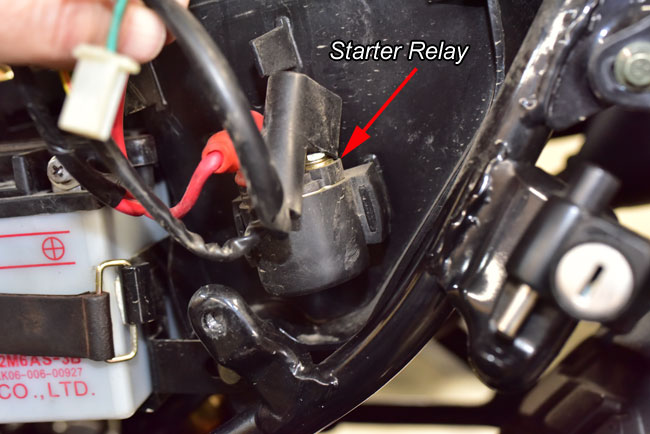

The starter relay is located on the left side of the motorcycle just to the rear of the battery. It closes when commanded to do so to send power to the starter motor.

As you can see in the above photo, the starter relay is attached to the frame with a rubber carrier that fits over tabs protruding from the frame. I removed it from the frame so you can see the wiring that sends a signal from the starter button to the relay.

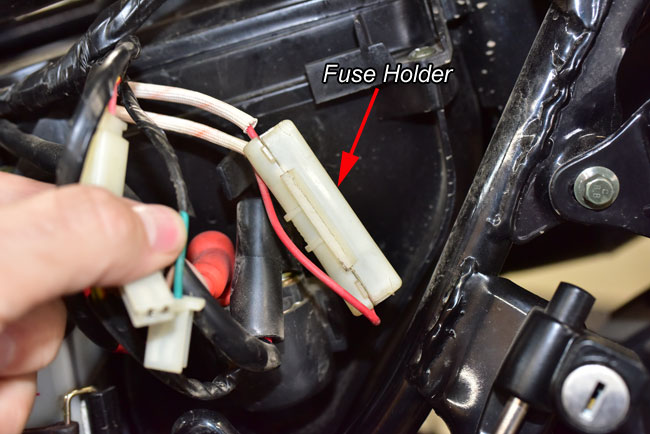

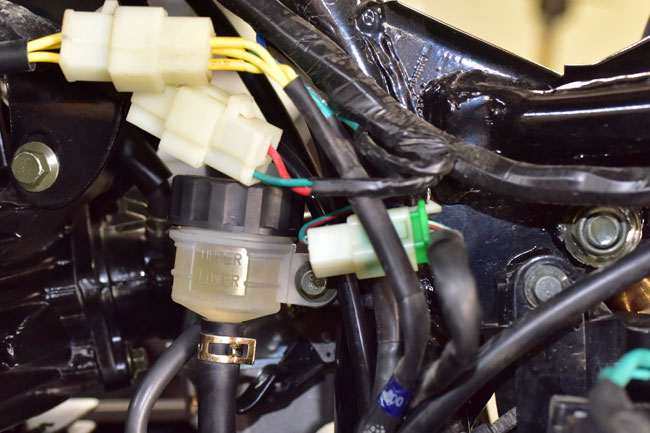

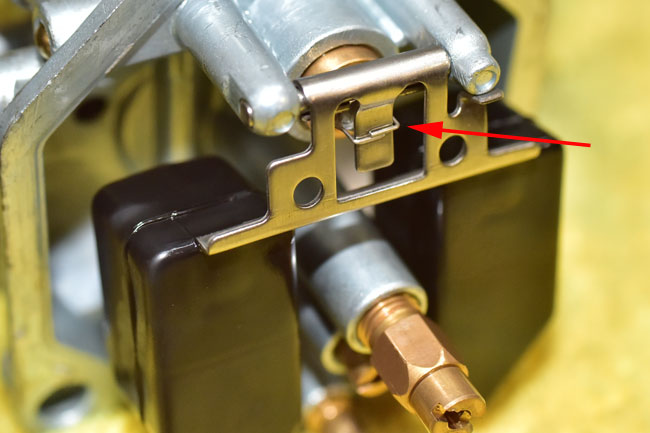

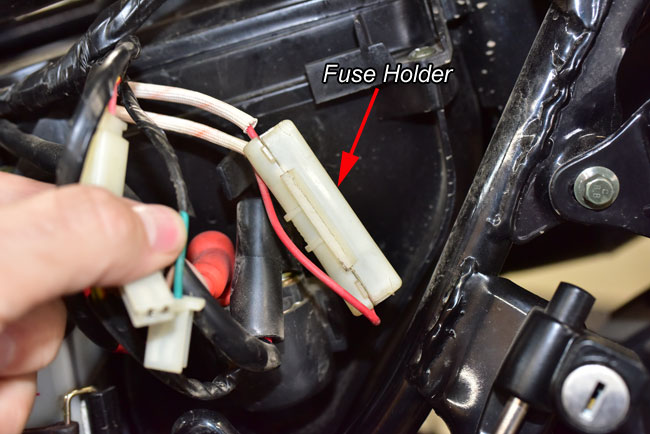

The motorcycle’s only electrical fuse is located in a carrier behind the battery. This pops open to provide access to the fuse.

If the motorcycle loses all electrical power, there are several potential causes, but the most likely are that this fuse has opened, or the engine kill switch is in the off position. Don’t laugh about that last one. We regularly get calls in which the caller tells us the bike has lost all electrical power. In those cases, it’s almost always because the owner inadvertently has the kill switch in the off position. I’ve done it, too. I’m just mentioning it here because it’s the first thing I would check having answered a few of those calls, and because I’ve made that mistake myself (i.e., leaving the kill switch in the off position).

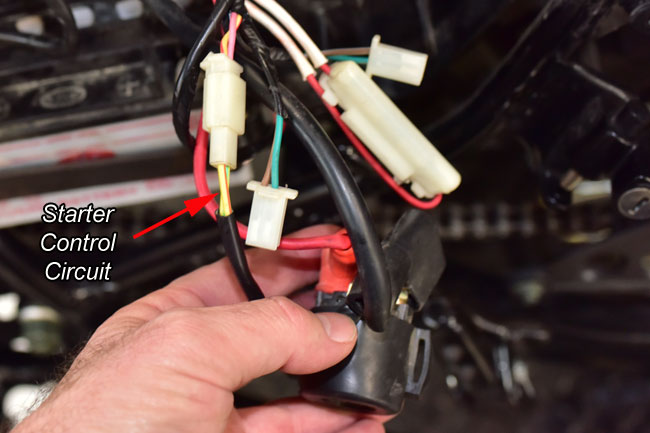

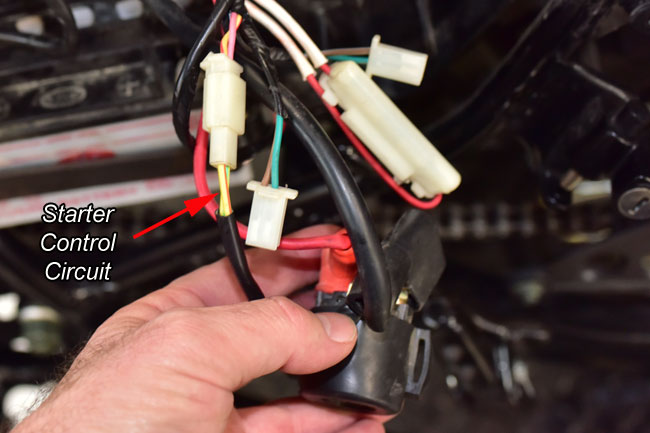

Several of the connectors and harnesses in the battery area (on the left side of the motorcycle) are identified below.

The two 12V underseat accessory outlet connectors are also on the left side of the motorcycle. These are controlled by the handlebar-mounted switch and they are provided as a convenient point for connecting accessories, heated vests, etc. When the ignition is off, power is cut to these connectors.

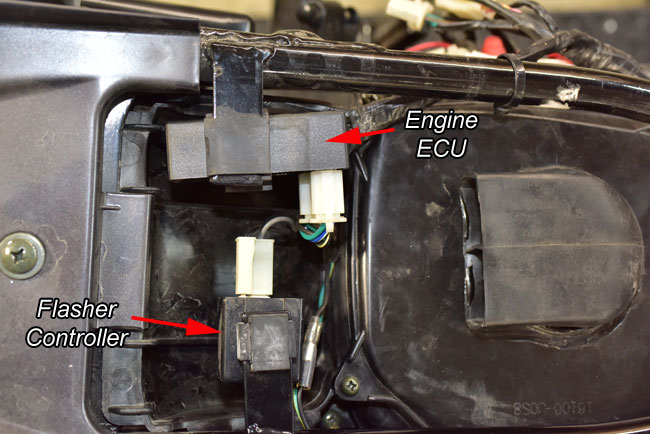

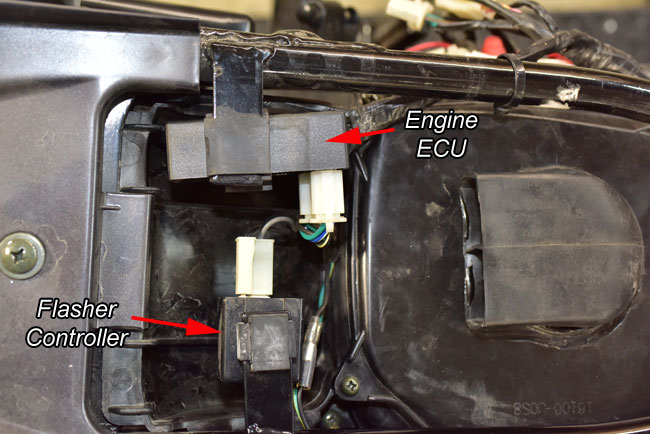

The engine ECU and turn signal controller are located beneath the seat.

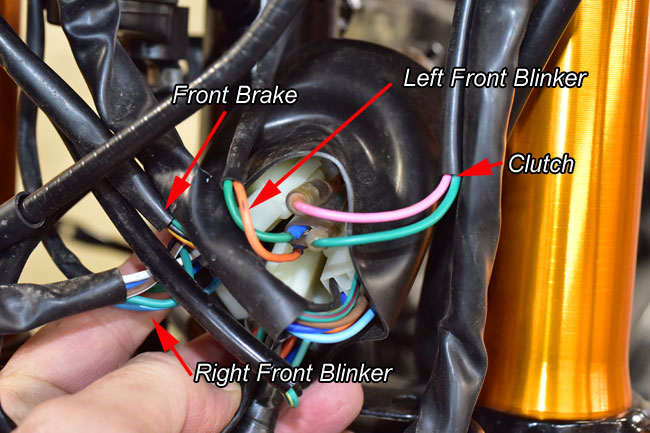

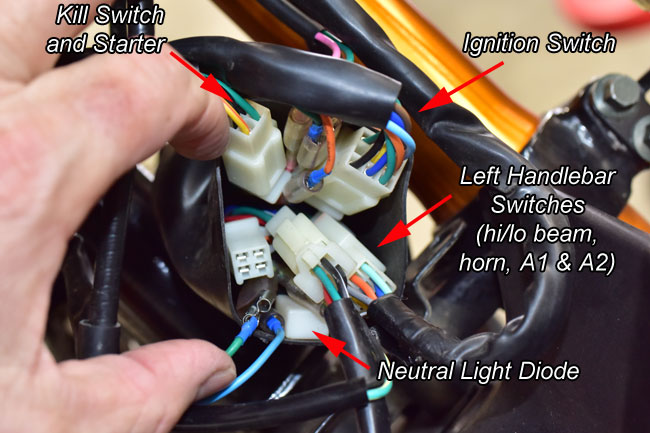

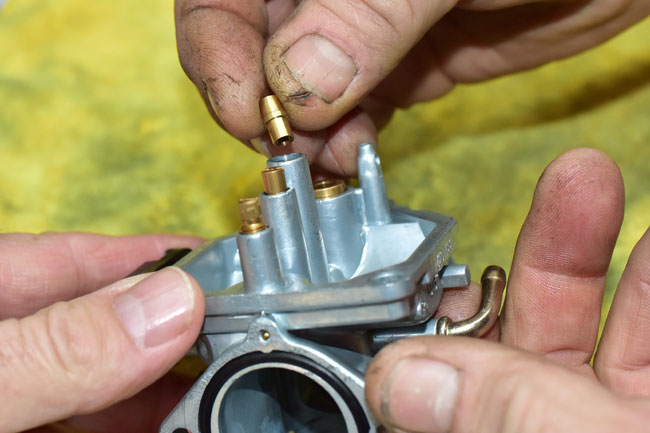

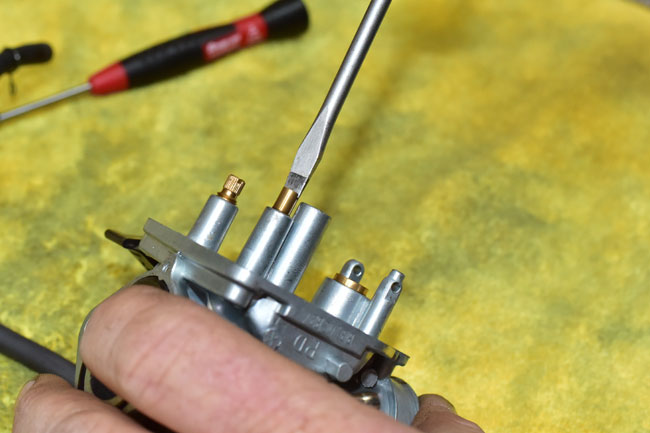

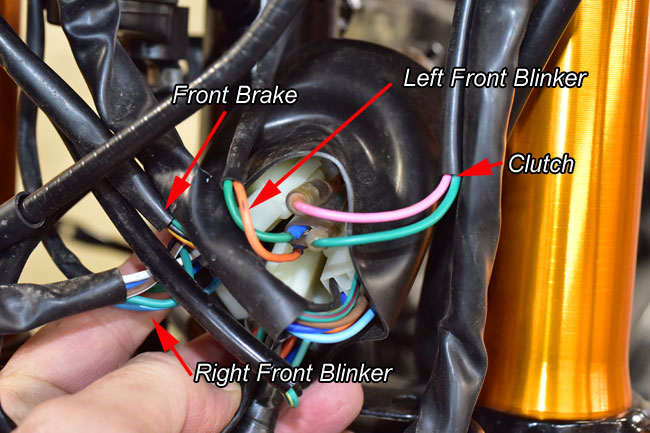

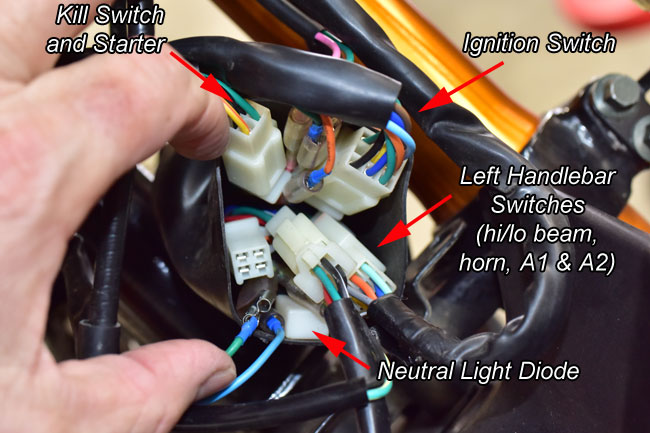

When the headlight has been removed, several connectors and harnesses are visible from the front of the motorcycle. These are identified in the photos below.

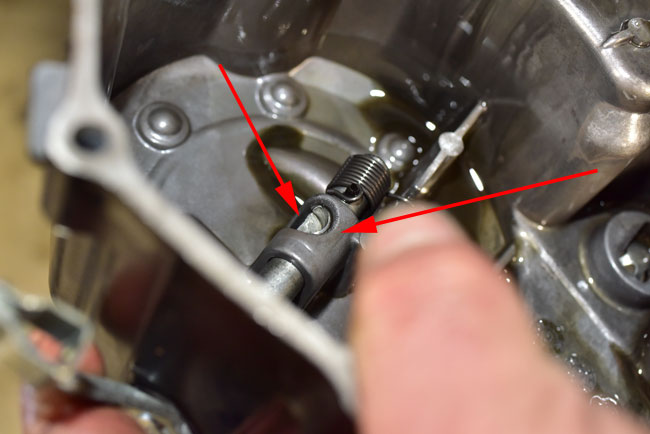

The neutral light diode controls when the neutral light is on. If it is shorted, it will allow the neutral light to come on whenever the clutch lever is pulled in.

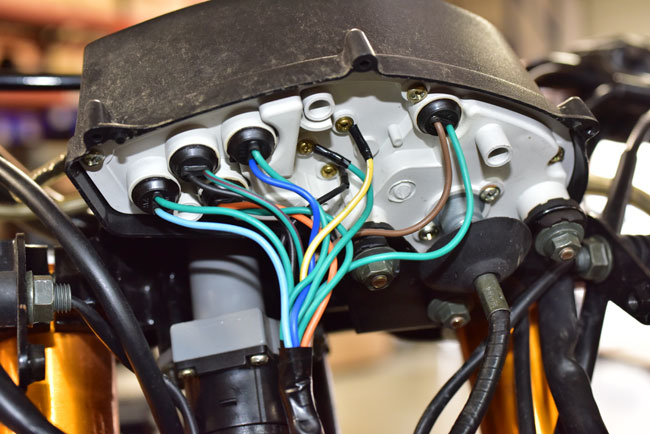

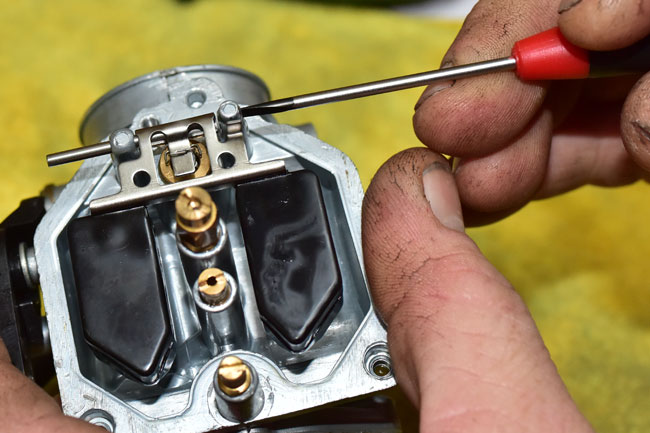

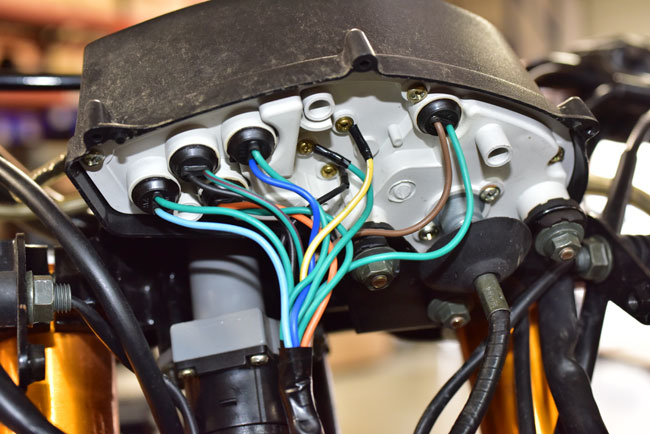

Access to the indicator lights and wiring is provided when the headlight nacelle is removed. The photo below shows the underside of the dash cluster.

The TT250 Service manual provides a wiring diagram, which can be used in conjunction with the above photos when troubleshooting any electrical problems.

TT250 Enduro

TT250 Enduro RX1E Electric Motorcycle

RX1E Electric Motorcycle SG250 San Gabriel Cafe Racer

SG250 San Gabriel Cafe Racer