Flat tires. It’s something we probably all worry about, and it’s something we all have experienced. The good news is that it doesn’t happen very often. The bad news is that when it happens, it’s usually out in the middle of nowhere and it’s up to us to fix it. This maintenance tutorial focuses on fixing a flat on your RX3. We’ll talk about the tools you’ll need, the approach, and how to do it.

First, a story. The first time I ever came head-to-head with a flat tire it wasn’t even on my bike; it was on my buddy John’s Virago. We were on one of our mega-expeditions in Mexico and we were riding through the jungle (no kidding, a real jungle) early on a Sunday morning somewhere way north of Puerto Vallarta. When I say a real jungle, let me put that in perspective: We were smack dab in the middle of where Liz Taylor and Richard Burton filmed Night of the Iguana. Like I said, a real jungle.

John was on his Yamaha riding alongside me on this empty rural road, we were dodging iguanas, and I noticed John’s front tire was nearly flat. I don’t know why ol’ Juan didn’t notice it. I motioned for us to stop, we pulled over, and there was no question….that tire looked about as dead as Pancho Villa. It had just a bit of air, but it was obvious…if we didn’t get it fixed soon, we’d be stranded. In the middle of the jungle. Somewhere in Mexico.

John didn’t seem too fazed by all of this. That guy will probably live to be 900 years old. Me, I’m a worrier. I had visions of trying to survive by eating monkey meat (yeah, we could hear them out there in the trees) or lizards. I remember thinking iguana probably tastes like chicken. John said maybe he just needed air. I explained to him how we were in the middle of the jungle on a Sunday morning, we hadn’t seen another car or human being in hours, and things were looking bleak. John’s only thought was that maybe we’d see something up ahead and we could get the thing fixed there. We hadn’t seen another structure for the last 60 or 70 miles. Nothing. Just trees. And lizards.

With me feeling deep despair and John being the eternal optimist, we slowly started out again. We didn’t want to go too fast; there could not have been more than about 8 psi in that front tire.

Son of a gun, we hadn’t gone a quarter of a mile when we rounded a bend on that jungle road in the middle of Mexico. Whaddaya know, there was a llantera (that’s Spanish for “tire shop”) on the right, tucked away in the trees, and it was open! On a Sunday morning. There must have been 12 or 15 people out in front, including a bunch of Mexican kids playing with old tires. It was a hot spot. I wondered if Richard Burton had ever been there.

John asked the guy who looked like he was in charge if he had air.

“Que?” was the response.

“Air,” John said again, a little louder. When someone doesn’t speak English, we Yankees always think if we say the same thing again louder they’ll comprehend.

No dice. The language barrier.

John made a hissing sound and pointed at his tire.

“Ah, aire,” the llanterian said. He pronounced it “aye-day.”

So, back to the main attraction. Most of the places we ride our adventure touring bikes aren’t going to be blessed with a Sunday morning llantera in the middle of nowhere, so we have to know how to fix our tires when they need fixing.

Here we go, boys and girls. Let’s fix a flat.

The first bit of advice I always give people is to check for any obvious cause of the flat tire on the outside of the tire. The reason you want to do that is it will make finding the leak in the tube a lot easier. If you can find it, great. You’ll know about where to look on the tube for the hole to be repaired. If you can’t find it, we still have a few tricks we can use, and I’ll get to those shortly.

At this point, let me digress and point a couple of things out. When you get a flat tire, you’re going to be stopped for a couple of hours. Don’t sweat it. It’s all part of the experience, and as a good friend once told me, when you’re on an adventure ride, the real adventure starts when things go wrong. Don’t get wound up. We’ll fix it.

Next point…while some folks swear by those “fix-a-flat” kinds of cans that you can just plug into a flat tire and make your cares go away, I’m not one of them. I’ve tried them a couple of times and I’ve never had good results. My advice is this: When you have a flat, you need to fix it. There are no shortcuts.

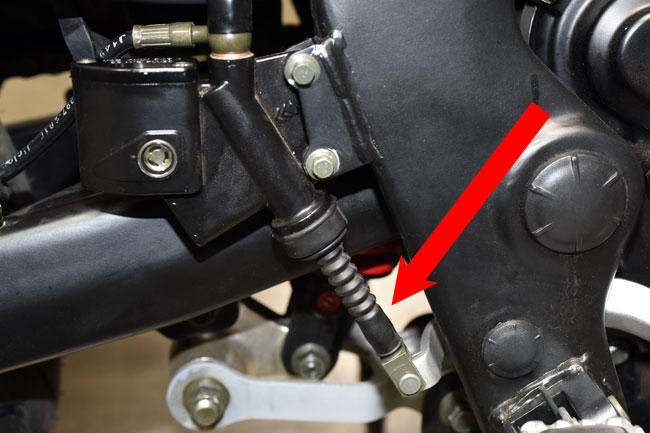

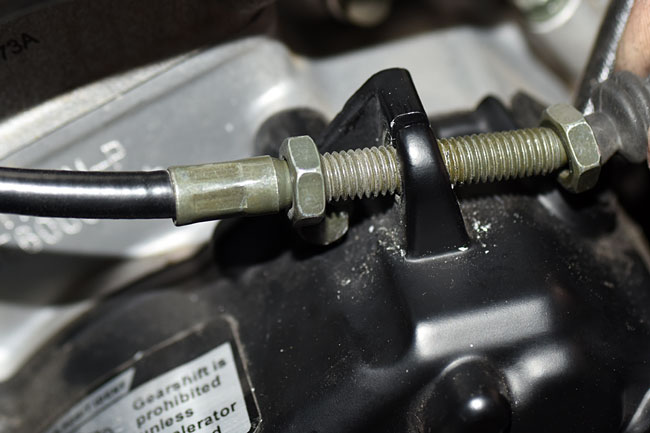

Before you prop up the bike so you can remove the wheel with the flat tire, loosen the axle bolts (just loosen them, do not remove them) . You want to do this before you get the bike in the air because once the bike is in the air, it won’t be as stable as it was when it was on the sidestand. Do the heavy torqueing (or maybe I should say un-torqueing) before you get the bike in the air.

Back to lifting the affected wheel…if you have our accessory centerstand, this is a lot easier to do. If you do not (and most of the bikes I’ve ever had are in this category), you need to find a way to prop up the bike so that you can remove the wheel.

Some folks just lay the bike on its side. I advise against doing that for a lot of reasons. Another approach is a prop that works with the sidestand to hold one end of the bike in the air. Yet another approach is to use our accessory maintenance center stand (see the photo below).

All of these things involve carrying more stuff on the bike. Necessity is the mother of invention, and if I need to prop up a bike, I’m going to find a way to do it…a fallen tree, a log, a box, or something that will get the bike off the ground. How you do that is up to you. The bottom line is that you’ve got to get the bike off its feet, so to speak.

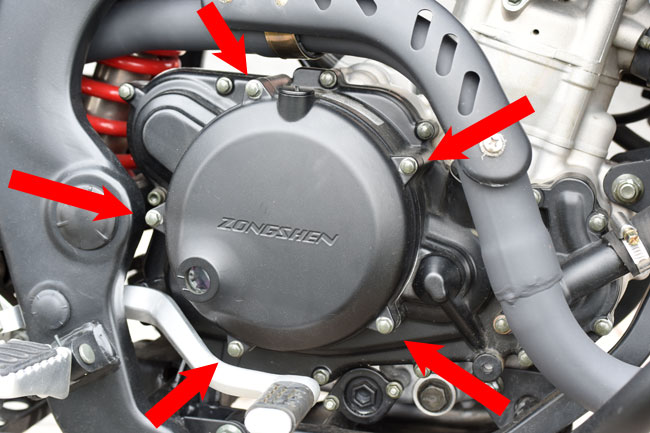

Once you’ve got the affected wheel off the ground, you need to remove it. Our photos here show doing this with the rear wheel because there’s more to removing the rear wheel than there is to removing the front wheel. Everything that follows in this maintenance tutorial pertains to the rear wheel only, but other than the nuts and bolts of the rear wheel removal process, what we have here is equally applicable to the front wheel.

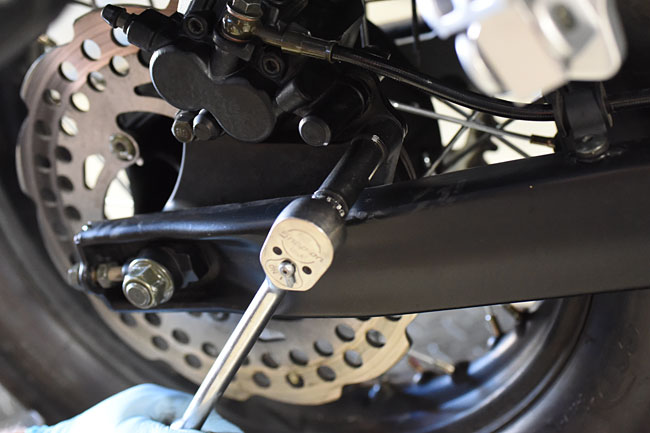

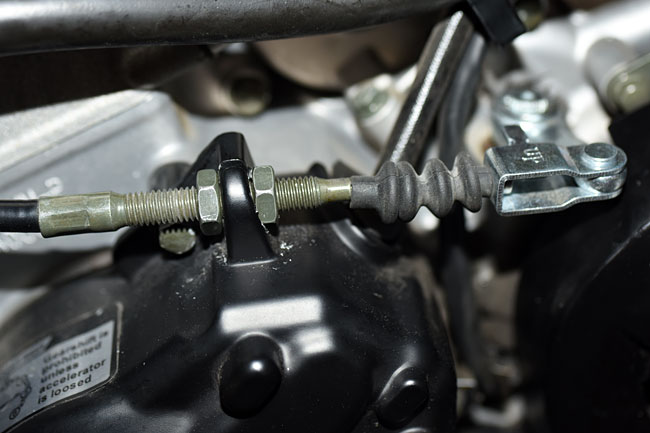

Remove the rear axle nut (it’s a 17mm; the bolt head on the other side is an 18mm) and pull the rear axle out from the left side of the motorcycle. You may have to tap it from the right side to get it started.

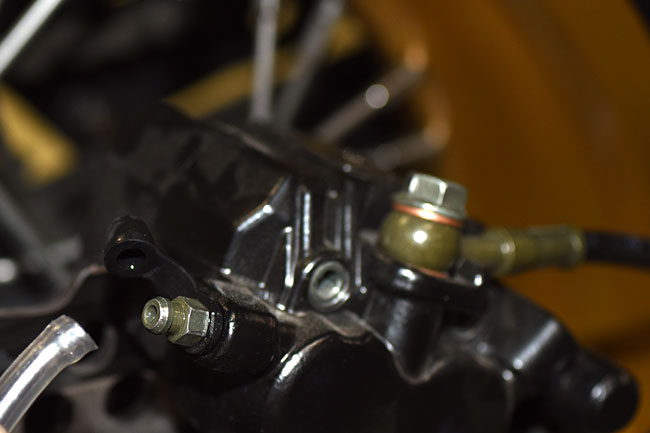

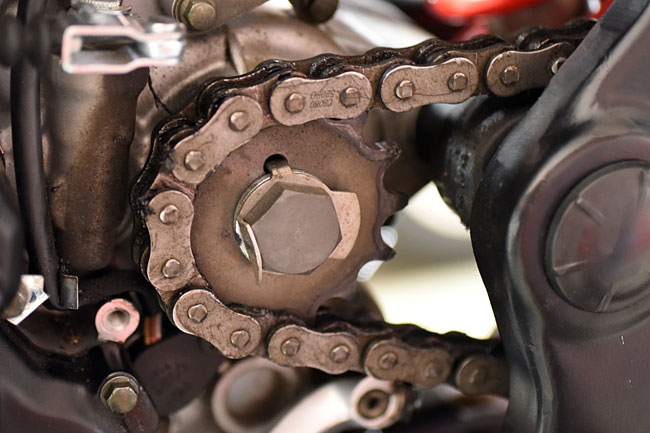

After you have removed the axle, push the rear wheel forward and lift the chain off the sprocket. Your hands will get dirty (don’t get your shorts in a knot over this; it’s all part of the adventure). On the RX3, you don’t have to remove the chainguard to get the chain off. Also, you don’t have to remove the rear brake caliper to get the wheel off the bike. You’ll want to make sure, though, that after you have removed the wheel, you don’t operate the rear brake (it will make reassembly challenging).

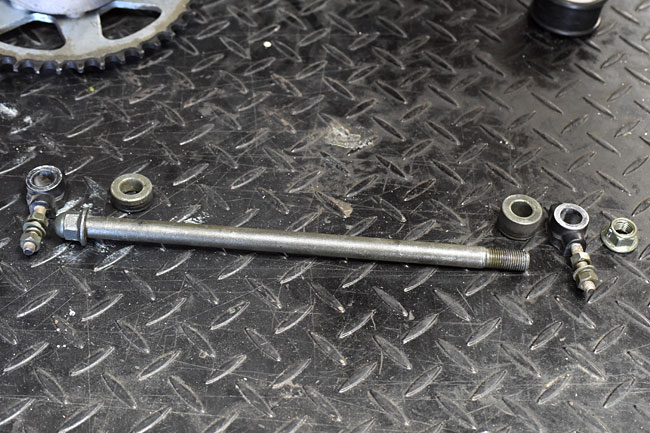

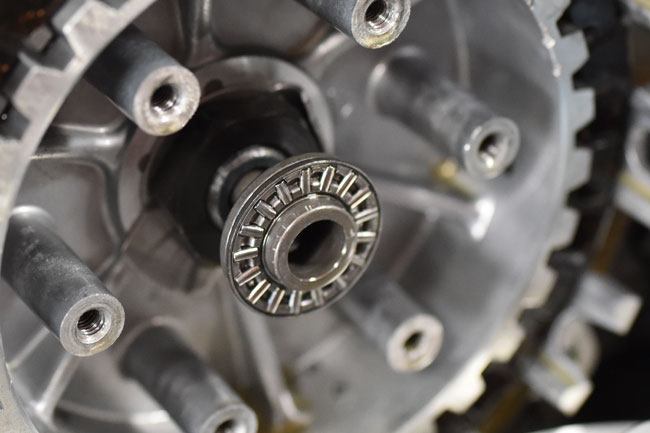

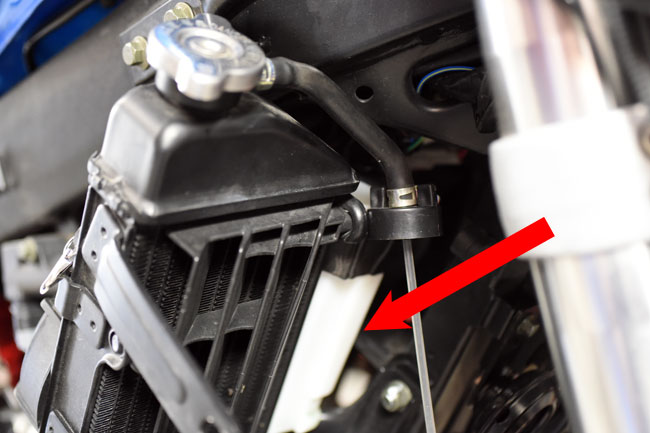

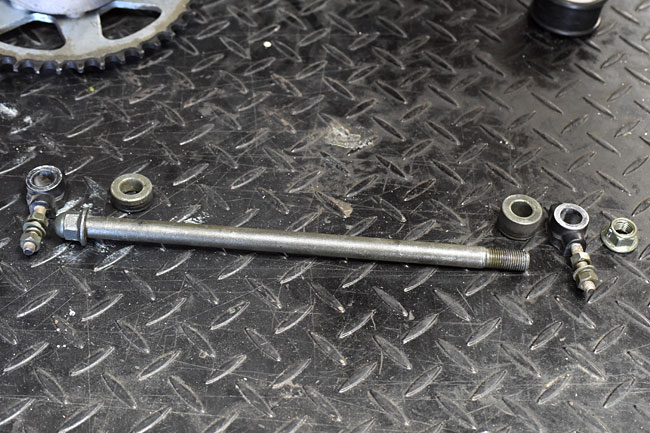

Once the chain is off the sprocket, roll the wheel out from under the motorcycle. On the rear wheel, there are two bushings (one on either side of the wheel). The thicker bushing goes on the right side of the motorcycle, and the thinner bushing goes on the left side of the motorcycle. You’ll want to remember that when you are reinstalling the wheel. You can see the order of the axle and the bushings in the photo below.

Here’s a shot showing Rich rolling the tire away from the motorcycle.

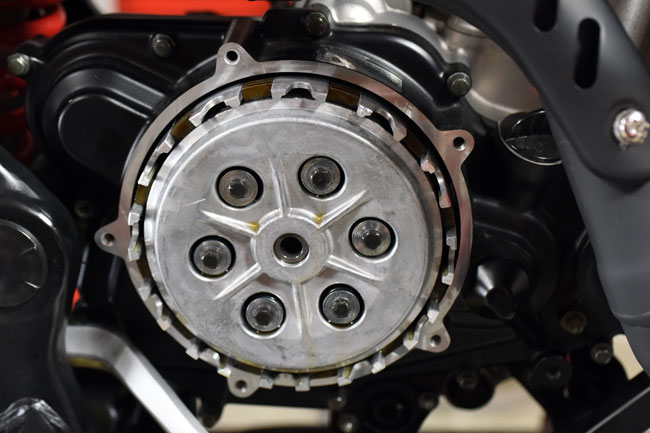

After removing the bushings, remove the sprocket and the cush drive, and set these items aside.

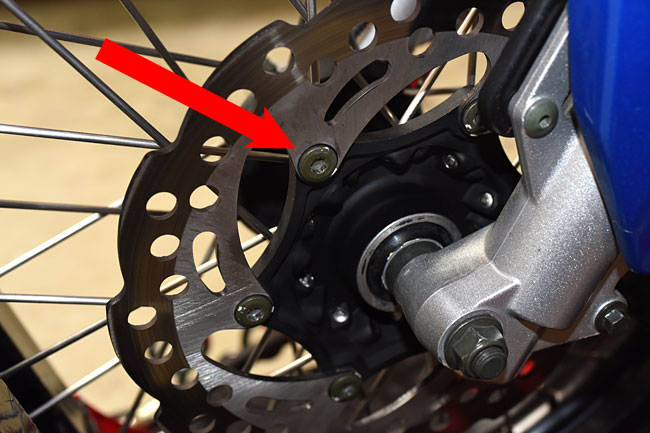

Place the wheel on its side, with the brake disk facing down (as shown in the photo below).

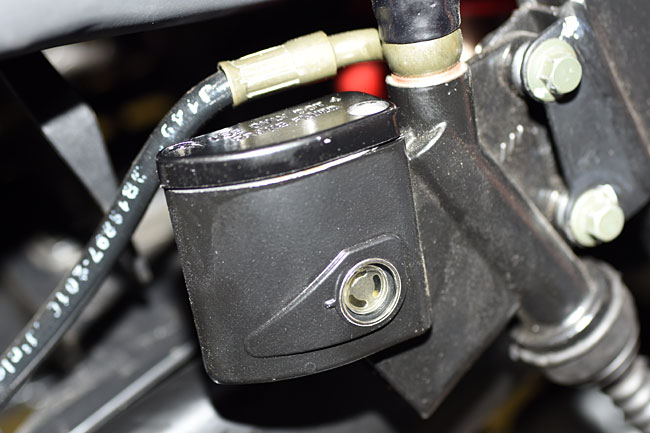

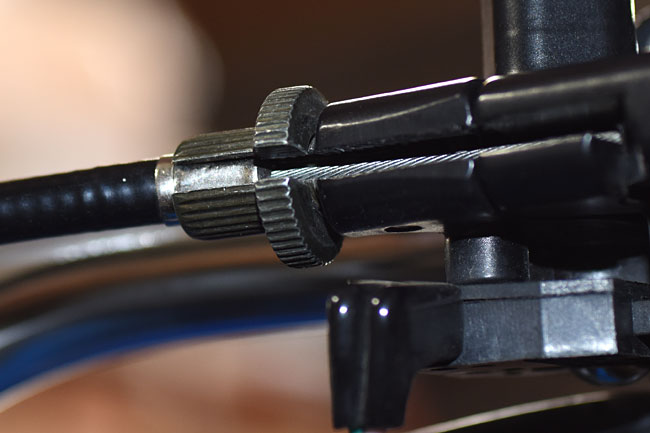

Even though you have a flat tire, there may still be residual air pressure in the tube. Remove the valve cap and depress the Schrader valve to allow any remaining air to escape. With a 10mm wrench, loosen the nut around the valve stem, and then unscrew it completely by hand.

The next step is to break the bead around the tire. The good news here is you only need to do this on one side of the tire. Usually, just stepping on the tire (as shown below) will unseat the tire from the rim.

In rare cases where the tire doesn’t want to separate from the rim, you might want to get two people to step on the tire. Other approaches for breaking the bead can involve using a c-clamp, or using another motorcycles’ sidestand (lean the motorcycle against the sidestand after putting the sidestand on the tire near the bead). These latter actions are uusally unnecessary, however. Most of the time, simply stepping the tire will break the bead.

After you’ve broken the bead, spray the area between the bead and the rim with a silicone spray lubricant (I like WD40, and I usually have a can of this in the saddlebag).

Using one of the tire irons (you’ll need two), insert the tip between the tire and the bead, and pull the bead over the rim. Using the second tire iron, pick a location about 6 inches away (measured circumferentially on the rim) and do the same thing. Remove the first tire iron and repeat the process. You usually only need to do this once and the tire will pop off the rim on the side you’re working. You do not need to remove the tire from the rim; you only have to get it off the wheel on one side.

At this point, push the valve stem back into the rim so that it is no longer passes through the rim. Remembering where the puncture occurred on the tire (if you were able to identify the puncture location), pull the tube out of the tire (you’ll be pulling it out between the tire and the rim on the side where you separated the tire from the rim).

Carefully inspect the tube in the area adjacent to the tire puncture location and inspect for the source of the leak. If you find it and if it is small (they almost always are), you can most likely patch it. If the tear is more extensive, you will have to replace the tube.

If you can’t find the leak, partially inflate the tube and listen for hissing. You may have to put the partially inflated tube near your ear and rotate it until you find the leak. If you are near water, you can immerse the tube and look for bubbles to locate the leak. If you hear it but can’t see it, you can rub spit around the general area and look for the leak.

People sometimes ask this question: Is it okay to patch tubes, or should I replace them? Here’s my advice: I don’t like to carry complete tubes because they take up a lot of space (and you’ll need two of them; the front and rear tubes are different sizes). I carry a patch kit, but I view the patch kit as a temporary fix. It will get me home or to the next town where I can buy a new tube. I don’t view a patch as a permanent fix.

Regarding a patch kit, we sell a kit for your RX3 that contains what you need to do everything described in this maintenance tutorial.

You can call us at 909 445 0900 to order the kit above or any of the other items we describe in this tutorial.

A bit of advice on patching a tube: The kit will say how long you should let the glue dry. Don’t rush it. Follow the directions. And one more bit of guidance: After you’ve patched the tube and allowed it to dry, partially inflate if before putting it back in the wheel and tire. You don’t want to find out the patch is no good after you’ve reassembled everything. Pump it up, spit on the patch and rub it around, and look for bubbles. If it passes our high-tech spit test, you’re good to go.

Before you reinstall the tube (either one you’ve patched or a new one), reach in with your hand and gingerly feel around the inside of the tire. You are looking for anything that might damage the tube when you reinstall it. You want to do this delicately because if there is something sticking into the tire, you don’t want to cut yourself on it. If you find anything, remove it.

After doing the above, deflate the tube and gently reinsert it into the tire. Position it so that the valve stem is aligned with the hole in the rim. Push the valve stem through the hole in the rim and then reinstall the 10mm nut on the valve stem to lock the valve stem in place. Gently tuck the tube completely in to the tire.

Now we need to reinstall the tire on the rim. You’ll able to get about 50% or so of the inside tire diameter over the rim with your hands. The remainder will have to be done with your tire irons. This is not a time to rush. Take things slowly and be extra careful not to pinch the tube between the tire and the rim (and don’t damage the tube with the tire irons) when you are reseating the tire. Liberal use of WD40 will help here.

Reinstall the tire and wheel on the motorcycle before you inflate the tube. This is the reverse of the process I described above.

After accomplishing all of the above, it’s time to inflate the tire and get it to seat on the rim. There are several approaches to this, too. In a perfect world, you’ll have a source of compressed air nearby (for example, if you can, you might make it to a gas station when you realize you are getting a flat tire). Most of the time we’re not that lucky. You can carry a small compressor that runs on the motorcycle’s electrical system. I’ve used these, they work well, and we sell those, too. Again, give us a call at 909 445 0900 for a price.

Still another approach is to use CO2 cartridges, and you guessed it, we have those, too.

There’s yet another approach, and that’s to carry a small bicycle floor pump. It’s low tech, but it works, and it will get the pressure high enough to seat the tire on the rim. You’ll get a workout pumping up a motorcycle tire, but then you’d get a workout if you had to walk out of wherever you got a flat tire, too. The disadvantage is space. Most inexperienced folks pack too many things on a motorcycle trip. I like using s small bicycle pump, but I don’t like all the space they take up.

So, you’ve fixed your flat tire, you’re ready to roll, and you have a good war story to share with your friends. You can even throw in the stuff about Night of the Iguana and being stranded in the jungle if you want (hey, it’s your story)!

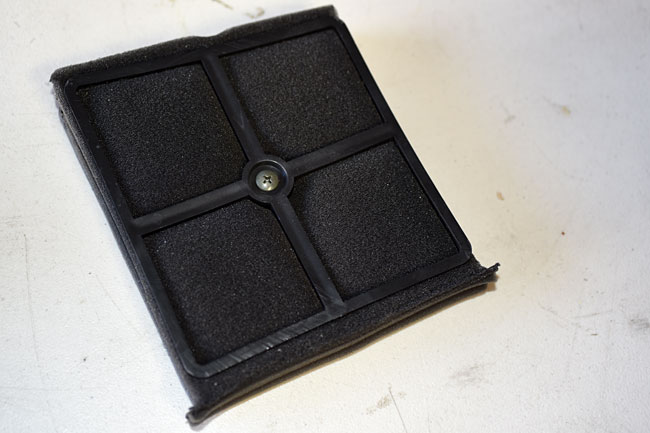

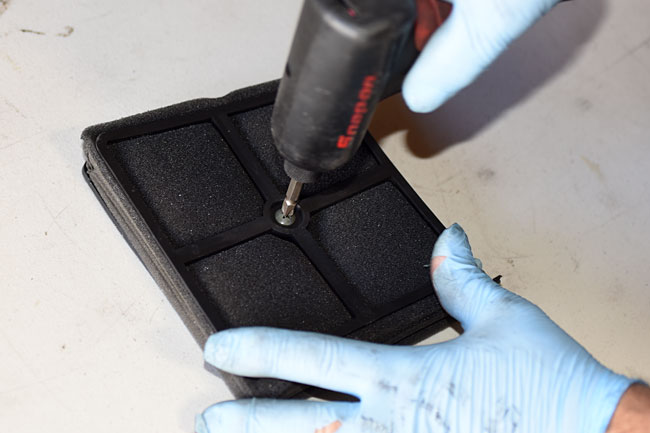

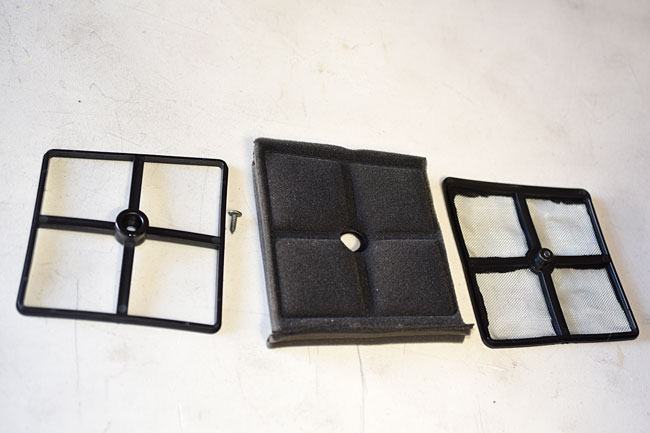

The filter element is a serviceable item. We recommend washing the air filter element in a solution of Simple Green and water.

The filter element is a serviceable item. We recommend washing the air filter element in a solution of Simple Green and water.

SG250 San Gabriel Cafe Racer

SG250 San Gabriel Cafe Racer RX1E Electric Motorcycle

RX1E Electric Motorcycle TT250 Enduro

TT250 Enduro